As a professional outdoor furniture company integrating design, production and trade, Beaconpeace specializes in providing high-quality, stylish and comfortable outdoor furniture solutions for users worldwide. Our product line covers a wide range of outdoor dining set, outdoor sofa set, patio umbrellas, daybed and lounger, etc. We are committed to creating comfortable outdoor furniture and providing a relaxing and cozy outdoor experience for you.

In our last blog, we introduced you to the process of drying outdoor furniture after it has been sanded and polished, and this time we move on to the next process, the powder coating.In the furniture industry, the spraying process, as an always important surface treatment technology, not only improves the aesthetics of the product, but also effectively enhances its durability and corrosion resistance.

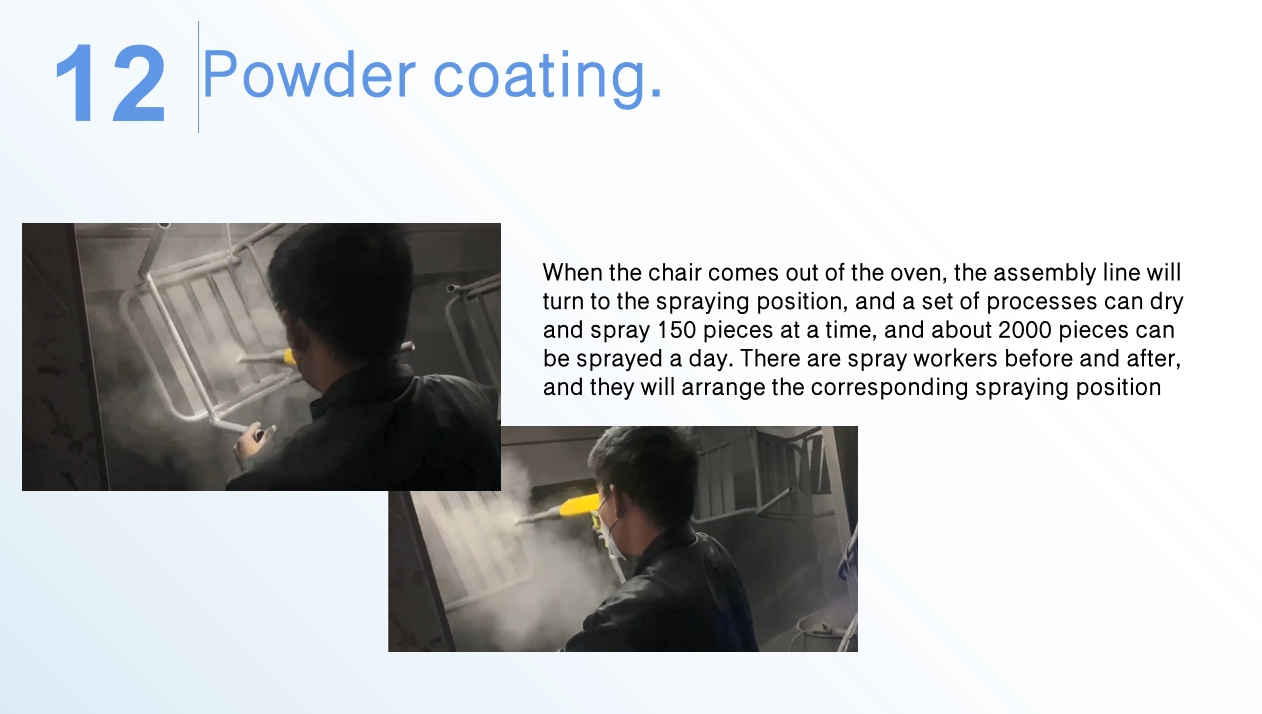

In an efficient coating line, the baking process takes place first. After being coated with powder coating, the chairs are fed into the baking oven for curing. When the chair is removed from the oven, the coating has formed a hard protective film on the surface, ready for the next step.In order to ensure the smooth running of the production line, the sprayers are divided into two positions, front and back, which are responsible for different spraying tasks. The sprayers at each station have to paint the chairs meticulously according to the production schedule. The front workers are usually responsible for the first coat of the chair, while the back workers are responsible for checking and perfecting the parts that are not fully coated by the front workers, ensuring that the surface of each chair is evenly covered. Workers are constantly coordinating their efforts to ensure that there are no delays in any part of the production line. The fine collaboration between the front and back stations not only improves work efficiency, but also minimizes waiting time between workers and ensures smooth production.

The efficient coating process ensures smooth operation and high productivity of the line. With a capacity of 150 pieces per coating and drying, the production capacity is up to 2,000 pieces per day, which meets the needs of mass production. Such a production line not only enhances production efficiency, but also ensures the uniformity and quality of the coating on the surface of each chair, providing strong competitiveness for manufacturing companies. In the future, with the continuous progress of production technology, the coating production line will continue to play its important role in improving efficiency and product quality.

With years of experience in the industry and stringent requirements for quality, Beaconpeace continues to innovate to meet the needs of different markets. Our products are made of weather-resistant and eco-friendly materials to ensure their superior durability and comfort in all weather conditions. At the same time, we focus on the combination of design and functionality, striving to provide our customers with outdoor living solutions that are both stylish and practical. If you are interested in our products, please contact us.