Beacon Peace Outdoor Furniture is an integrated industrial and trade manufacturer specializing in the production, manufacture and sale of furniture for outdoor use.We have modern production equipment and a professional team dedicated to producing all kinds of outdoor furniture, such as outdoor tables and chairs, outdoor sofas, lounger, parasols, etc. Our outdoor products are widely used in home residences, hotels, resorts, parks, gardens and other outdoor places.

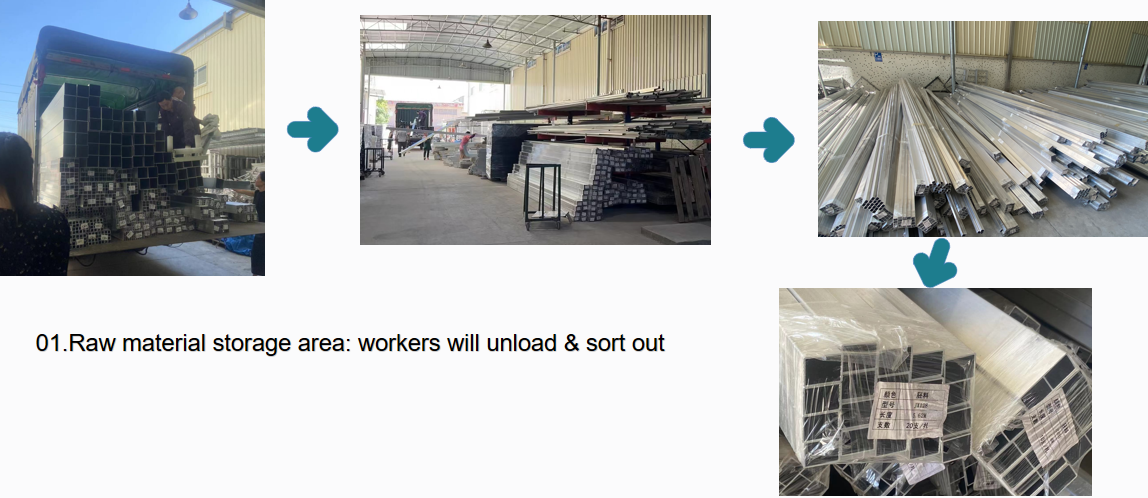

Our production as an outdoor furniture factory usually starts with the procurement of raw materials, such as metal, wood, plastic, etc. The raw materials are then processed into components of various shapes and sizes, such as table tops, chair backs, chair legs, etc. Next, the parts are sprayed, baked, and otherwise processed to increase durability and waterproofing. Finally, the factory performs assembly, packaging and quality inspection before the product is shipped out for sale.

This blog will first introduce the preparation of materials.The outdoor furniture we make now is made of aluminum alloy as the main material, plus outdoor rope, PE rattan, plastic wood, outdoor cloth, textile cloth, teak, glass, HPL board, rock board and other materials. Let’s first talk about the aluminum alloy of outdoor furniture. Aluminum alloy is composed of aluminum, magnesium, and magnesium silicide (Mg2Si). It has good plasticity, weldability, and a certain hardness.

Our aluminum alloy thickness is generally between 1.2 and 1.5 mainly. For aluminum alloy, we generally use the national standard 6063 aluminum alloy. 6063 aluminum alloy is extruded, so there are more choices in terms of pipe shape, and the mold cost is relatively cheaper than special-shaped pipes. If the customer needs to use special-shaped tube styles, the product will generally be more expensive because of the high cost of molds. Moreover, the preparation time for special-shaped pipes also takes longer, which increases the production time.

Since aluminum pipes usually take two weeks to arrive after ordering, and pre-production samples take 8-10 days, as well as the time spent preparing other production materials, our delivery time is generally 45-60 days. Of course, ordering existing styles and quantities will affect the reduction or increase of production time. So if you want to customize, please order it as soon as possible according to your needs. If you want to know our catalog, please feel free to contact us.